| Min. Order: | 1000 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,FAS,DDP,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | L/C, D/P, D/A, T/T, WU |

| Place of Origin: | Zhejiang, China (Mainland) |

| Means of Transport: | Ocean, Air, Land, courier express |

| Production Capacity: | 10thousand pcs per... |

| Packing: | neutral, 330x260x150mm... | Delivery Date: | 2-4 weeks |

|---|---|---|---|

| Shape: | Disc | Type: | Permanent |

| Application: | Motor Magnet | Composite: | NdFeB Magnet |

| Brand Name: | MaximMAGNET | Coating: | Nickel-Copper-Nickel, Zn, Epoxy, Phosphate |

| Density: | 7.5g/mm³ |

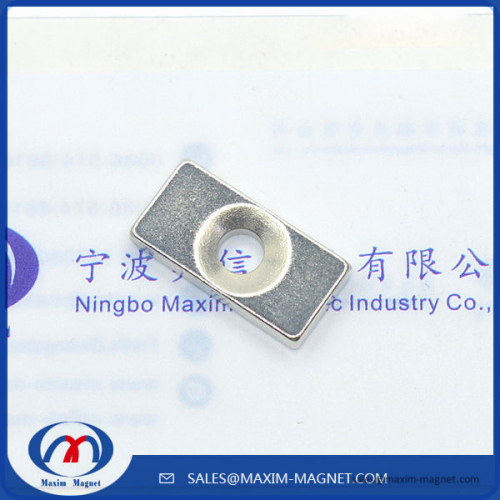

1.Shapes

Custom made neodymium disc magnets with countersunk holes;

2. Size

Customized size: according to your requirements/drawings.

Tolerance: +/-0.05mm, +/-0.1mm or according to your request.

3. Grade

N35-N52, N35M-N50M, N35H-N48H, N35SH-N48SH, N28UH-N40UH,N28EH-N35EH, N28AH-N33AH;

4. Coatings

Ni, Ni-Cu-Ni, Zn, Tin, Epoxy, Ni-AG, Ni-Au, Passivation, Parylene, Everlube, etc.

5. Production Time

2-4 weeks roughly.

6. Certification and Quality Control

ISO9001: 2008, strict quality control ensuring no magnets with unexpected defections;

7. Applications

Home application, Magnetic holding, Electric Motors, Generators, Wind turbines, Sensors, Speakers, Earphones and other musical instruments, Magnetic therapy devices, Magnetic Chuck, magnetic bearings and couplings, NdFeB Pot Magnet and other magnetic applicatications.

8. Directions of Magnetization

A. Thickness Magnetized

B. Axially Magnetized

C. Diametrally Magnetized

D. Multi-poles magnetized

9. Features

a. The magnet grades in N series are available from N35 to N52 grade (redisual magnetism from 11.7KGs to 14.8KGs);

b. Competitive prices;

c. Reasonable delivery time;

d. Good in-house inspection, ISO certified;

e. Free samples available;

f. Experienced sales staff who speaks good English, offering quick and good service.

All our magnets are customized made, so your kindly email us following information will be highly appreciated.

1. Dimensions, drawing is preferrable.

2. Magnet grade you're looking for;

3. Coating of the magnets: NiCuNi, Epoxy, Zinc, Passivation etc.

4. Magnetized direction;

5. Quantity;

6. Constant working temperature;

7. Your information on how you use magnets in your applications will always be appreciated.

Category: Countersunk magnets

Related Category: Ring magnets Motor magnets Magnetic balls Block magnets Disc magnets